P475 – 1/2″ UHV sputter deposition HZB

Application

UHV sputter deposition system for thin film and multilayer deposition at 1/2″ substrates

Year of delivery

2020

Installation site

HZB, Berlin, Germany

Design Features

- UHV magnetron sputter deposition system in confocal sputter up configurations.

- Up to five 2″ magnetrons in confocal configuration.

- All magnetrons with manual in situ source tilting.

- All magnetrons with easy changeable magnetic system for use with ferromagentic or non-ferromagnetic target materials.

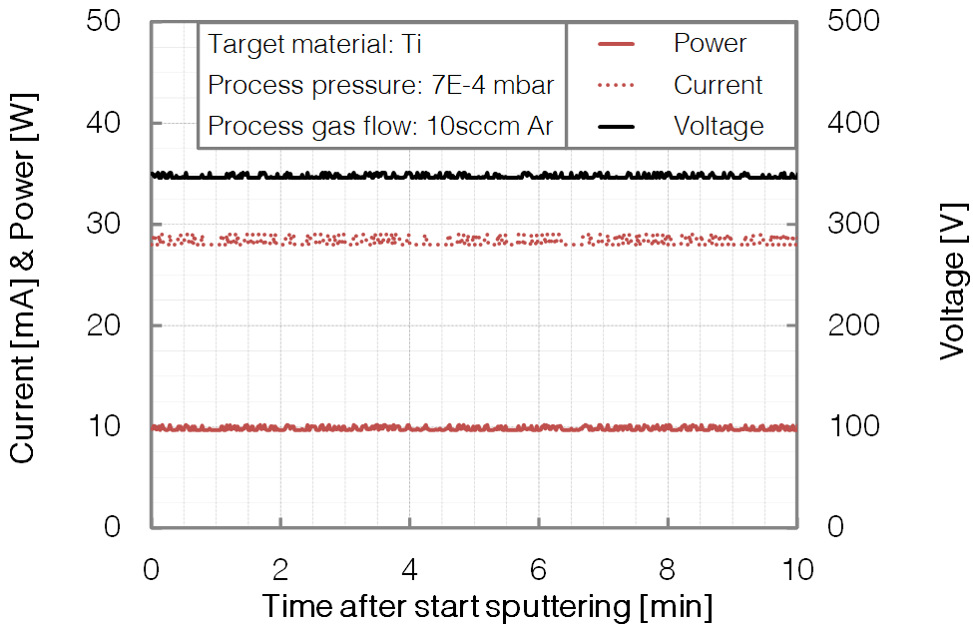

- Low pressure and low power sputtering possible.

- Partly motorized 4 axes sample manipulator with integrated pneumatic sample shutter, sample cooling and sample heating.

- Motorized x-y translation.

- Manual z translation and stage tilting (phi rotation).

- Minimum sample temperature below -100°C.

- Maximum sample temperature above 700°C.

- Ion source option for sample precleaning and mild etching.

- Thickness sensor setup with manual translation stage for sputter rate check before deposition.

- Integrated bake out system.

Special Features

- Two magnetrons can be additionally used in face to face configuration or in glace angle deposition configuration by sample stage tilting.

- System is prepared to be part of a cluster tool, beam line systm or other type of vacuum system.

- Later adding a load lock chamber possible.

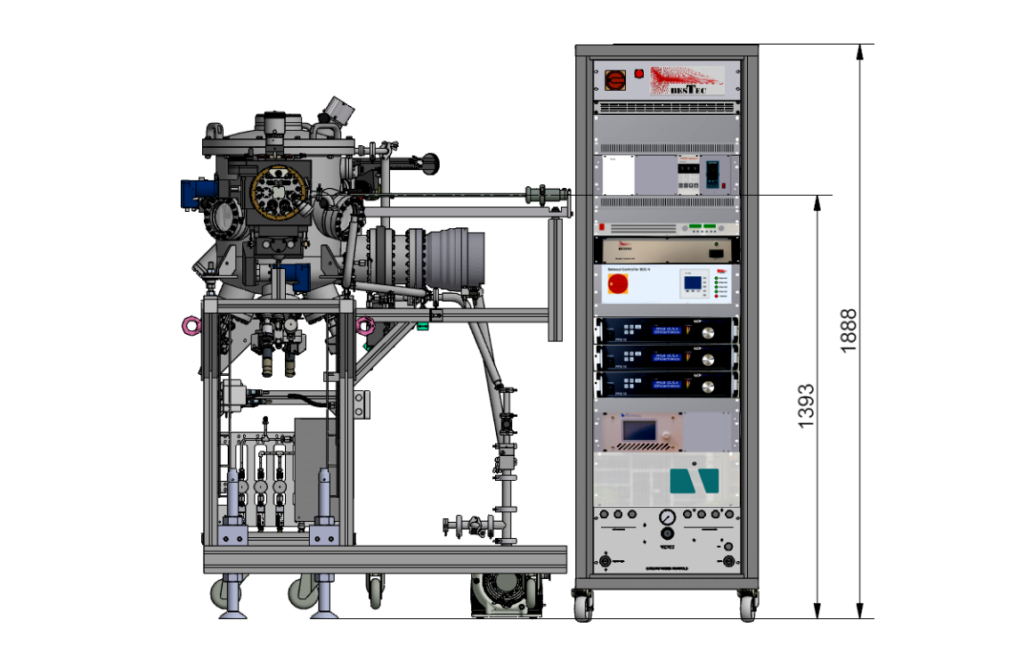

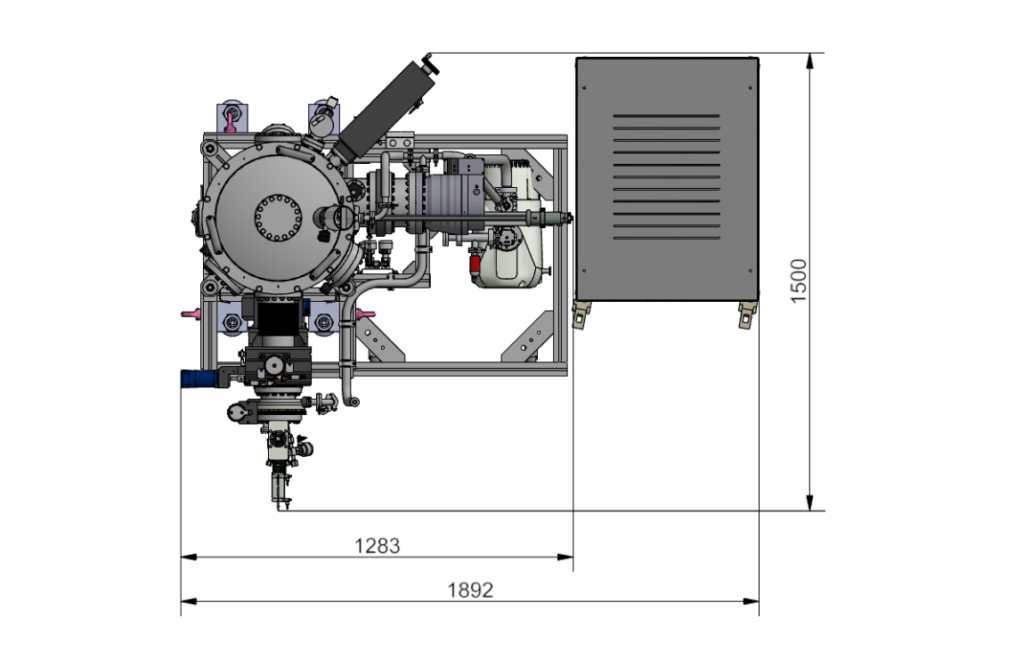

Outer Dimensions

Technical specifications and performance values

General

Sputtering chamber

Size

400 mm diameter, about 600 mm height

Material

stainless steel

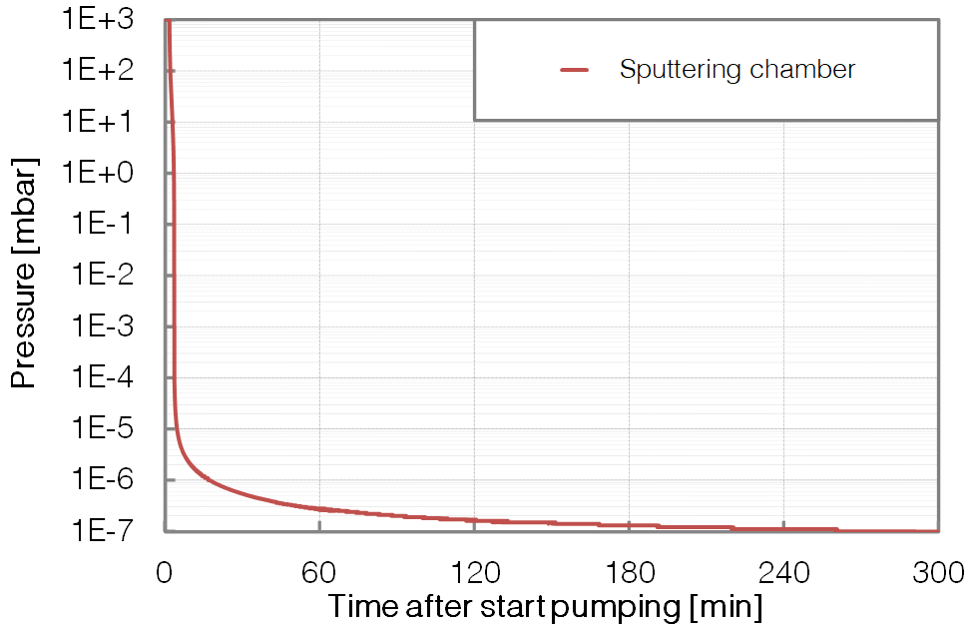

Vacuum

Sputtering chamber

Base pressure

< 7 * 10-9 mbar

Pump down time

< 5 hours to < 10-7 mbar

Chamber pumping

Turbo pumping stage, chamber lid differentially pumped by dry foreline pump

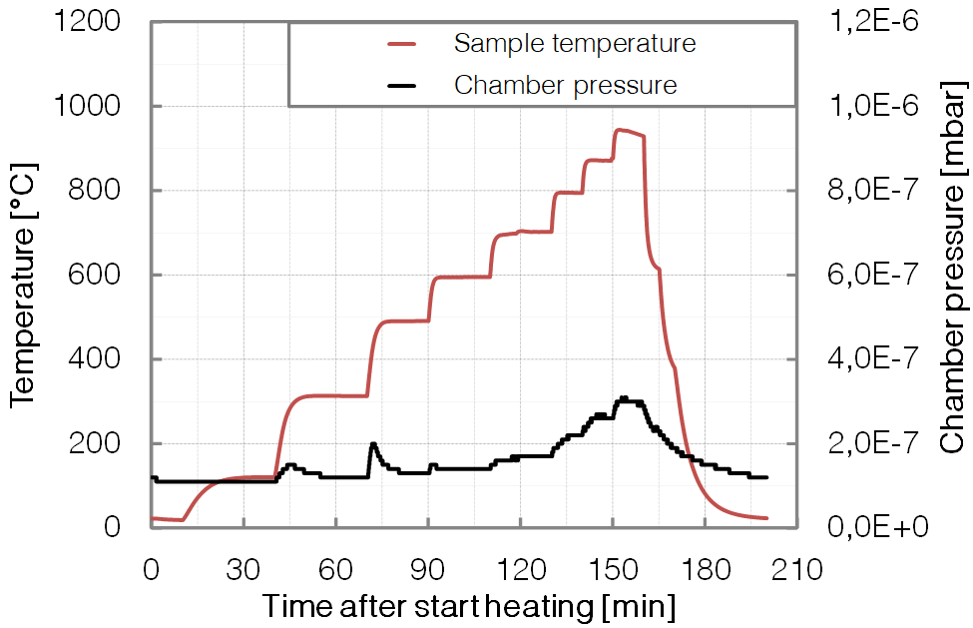

Bake out

< 150°C

Manipulator features

Sputtering chamber

Sample size

diameter max. 1/2″ substrate

Motion axes

4 axes (motorized x-y translation stage, manual z tranlsation and manual sample stage tilting)

Temperatures

< -100°C (not stabilized) up to 900°C at sample (short time heating) / > 700°C at sample (long time heating)

Special features

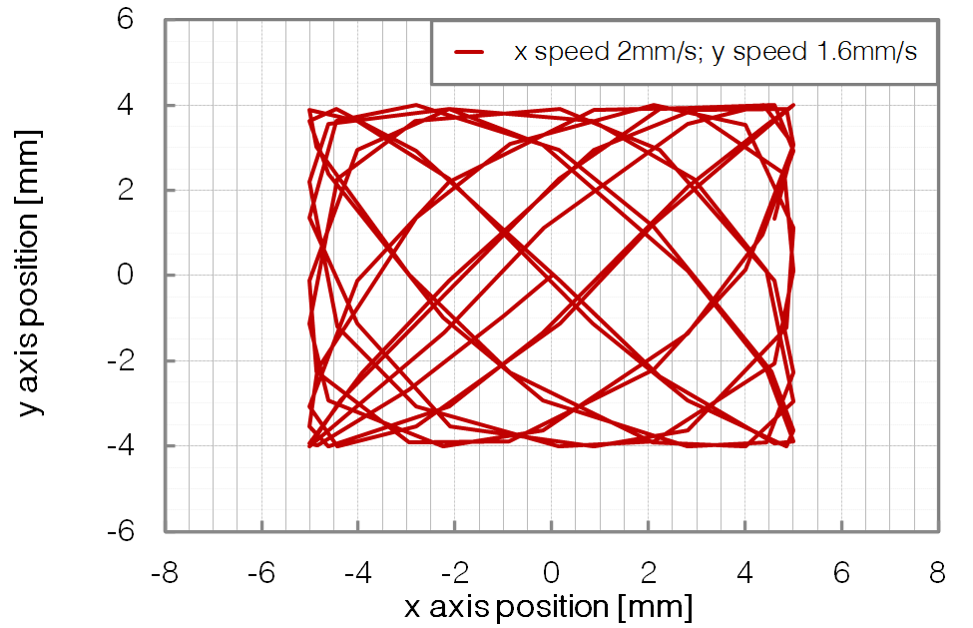

Software controlled wobble motion in x-y plane.