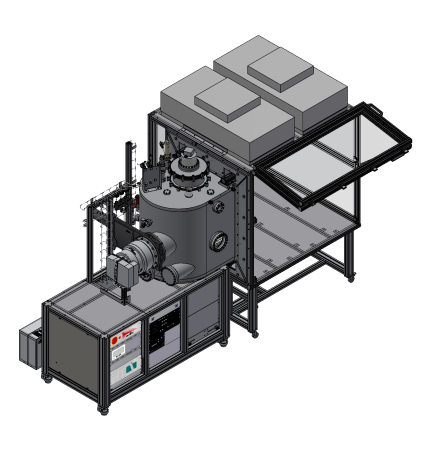

P462 – 9″X9″ HV Ion beam etching NOB

Application

HV ion beam etching system for surface structuring of max. 9″ x 9″ substrates

Year of delivery

2019

Installation site

NOB, Berlin, Germany

Design Features

- HV ion beam etching system with focused gridded RF ion beam source.

- Fully motorized 3 axes sample manipulator (x, y, phi sample stage).

- Laser based sample stage alignment for reproducible assambly after service at sample stage.

- Flow box integration.

Special Features

- Different sample sizes from 2″ wafer up to 9″ x 9″ samples can be handled.

- Vector motion in x-y plane (linear and circular).

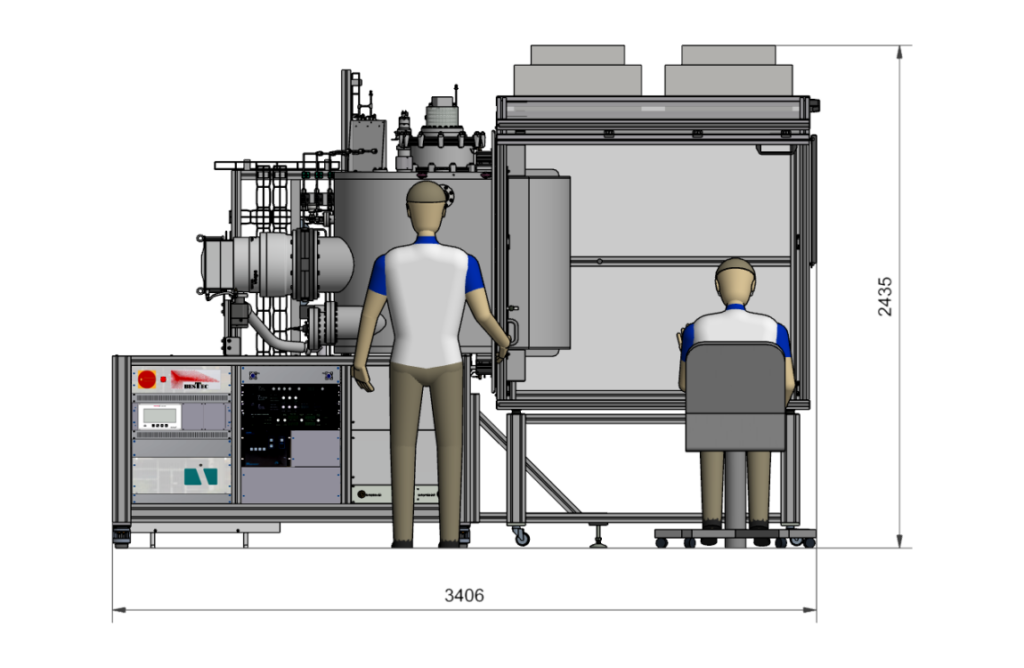

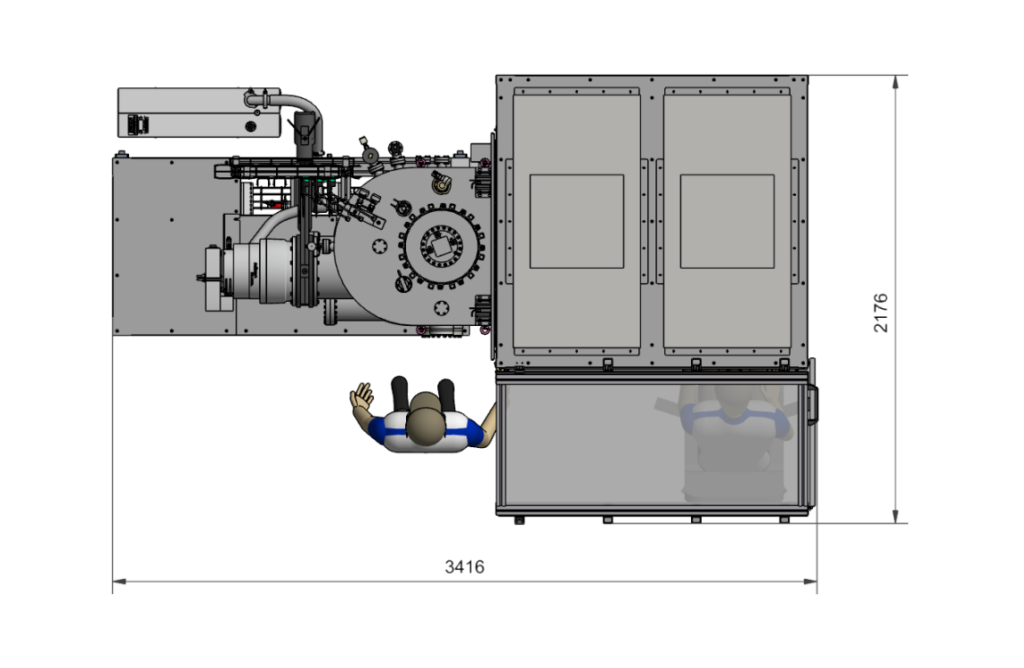

Outer Dimensions

Technical specifications and performance values

General

Etching chamber

Size

About 750 mm width, about 700 mm depth, about 1000 mm height (D-shape chamber with door)

Material

stainless steel

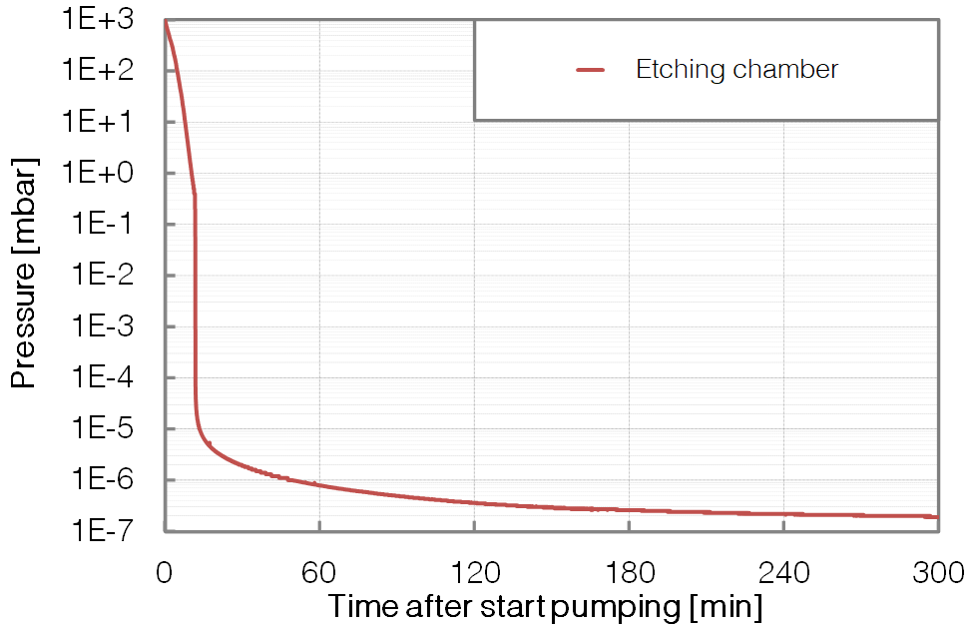

Vacuum

Etching chamber

Base pressure

< 2 *10-7 mbar

Pump down time

< 1 hour to < 10-6 mbar

Chamber pumping

Turbo pumping stage, chamber lid differentially pumped by dry foreline pump

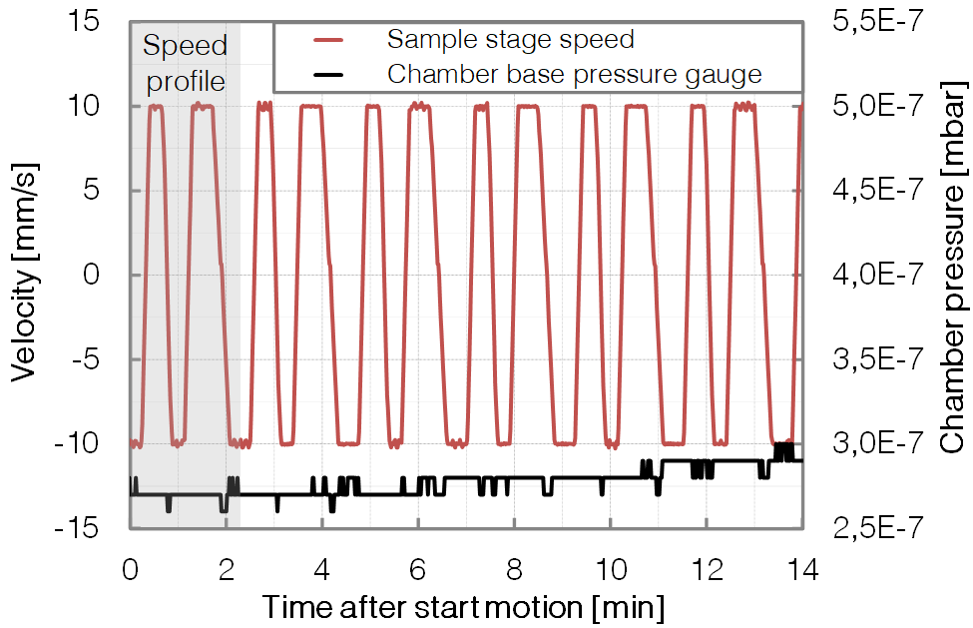

Manipulator features

Etching chamber

Sample size

max. 9″ x 9″ substrate

Motion axes

3 motorized axes (x tranlsation, y translation and sample stage rotation)

Special features

Vector motion in x-y plane (linear and circular).